Getting the correct Door Closer can be difficult, but with a little back ground on there rating, materials, operation, type and new or replacement it is pretty easy.

A door closer has three rating levels in the industry, Grade 1, 2 and 3. Grade 1 is the heaviest duty rating and is usually means it has passed a 10,000,000 cycle test. Grade 2 is the next lowest rating, and they are tested for 2,000,000 cycles. Grade 3 is the lowest and the level is 1,000,000 cycles. The testing agency puts the closer on a test bed and lets them cycle through until they fail. They usually give up on Grade 1 closers after they get past 10,0000,000 cycles.

A door closer is usually made of cast aluminum or cast iron. Many of the inexpensive models are constructed of cast aluminum, and the more expensive door closers are made of cast iron. Cast aluminum is a softer material and over time will wear. The seals and adjustment valves on the aluminum closers will also wear and tend to leak over time. Cast iron is much more durable, and is very hard. We tend to see less issues with cast iron. If your door is going to have high traffic, or is in an abusive atmosphere I would recommend a cast iron door closer.

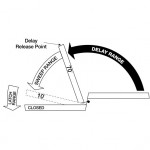

A good quality door closer will control the door when opening and closing. In the opening cycle it should create the least amount of resistance when opening and get more difficult toward the 70 degree point when the back check kicks in. Back check will control the door in case of a wind gust, or some one being abusive, kicking the door open. Back check will control the door so it does not slam into the door stop, or possibly a wall, and prevent the door from over rotating and damaging the hinges.

During the closing cycle the closer should close the door at a controllable speed. We have two controls and sometimes three. Just about every door closer made has a Closing and Latching Speed Valve. The Closing Speed valve controls the door from about 70 degrees down to the last 10 to 15 degrees. By tightening the valve you restrict the flow of hydraulic fluid flowing through the valve and it slows down. Latching Speed is amount of time it takes the door closer to swing the last 10 to 15 degrees.

A door closer can have a fixed spring or an adjustable spring. For almost 80 years door closers were shipped with a fixed spring. If you tried to install a size 5 spring on a smaller interior door it would of taken Hercules to open the door. In the 1970’s they started to manufacture adjustable spring tension door closers. With the adjustable spring you can adjust the tension the closer creates. If you have an interior bathroom door, you can turn the spring tension down so the door is easy to open, or if the door is exterior, you can increase to help close the door even if there is positive pressure in the building. Now schools and institutions could stock one door closer instead of many.

A door closer is going to be application specific or universal. Application specific means they are designed for one type of mounting and one hand. We have 3 types of mounting, push side (parallel arm), pull side (regular arm) or top jamb (top rail). For application specific a door closer would be designed for just one of the mountings. We do not see many of these anymore, but LCN Closers has the 4110 (parallel arm), 4010 (regular arm) and 4020 (top jamb). These application specific closers are usually more heavy duty, and last a long time. Universal door closer means they can be mounted on either of the three mountings, and are non handed, meaning they can go on a left or right hand door.

We also have size considerations for a new door closer. We have slimline and heavy duty closers. A Slimline door closer is one that has a 3/4″ center to center hole spacing on the vertical holes. This was done back in the late 1960’s with the advent of the narrow stile aluminum framed storefront door systems. The slimline closer was designed to mount on the top rail or top jamb, so it had to be narrow. The heavy duty closer is usually about 2-1/2″ on center for the vertical holes. The distance on the horizontal spacing does not matter, but the vertical height does.

Now that we have some back ground on the door closer, we need to figure out what your needs are. Is it for a replacement of an existing closer or is it a new door and closer.

If you are looking for a replacement closer, the first thing I would do is look for a manufacture name on the closer. If your closer has a cover, you might have to take the cover off and look on the inside of the cover for a model number, or it might be on a sticker. A little bit of information goes a long way. When we are helping customers find a replacement, we try to match the hole spacing, so there is very little work to do to install the new one. We have a Door Closer information page on our website, that lists the most common door closers and there hole spacing, this is a great place to start. With the knowledge you gained from the above information, you might even determine you need something more heavy duty.

Another thing we find on a door closer is a Listed Door Closer sticker. We usually find some thing like 320G Listed Door Closer. This is a UL sticker, or Underwriters Laboratory number. While it does not tell us which model you have, it does narrow it down to the manufacture you have. In this case 320G is a number we find on a LCN Door Closer.

If you are looking for a new door closer on a new door, I would ask yourself a few questions. How much traffic is the door getting, what is the weight of the door, what is the width of the door, does it have to be ADA compliant, how much room do you have to install the closer, how far does the door have to swing (90 or 180 degrees)

If you are installing it on a public building and every patron will be using this door, you might want something more heavy duty. But if you are installing it on your residential garage door, you might want something in the Grade 3 range. If you are installing a closer on a Public Library, than you definitely want to go Grade 1 Heavy Duty.

What is the weight, height and width of your door? If you have a wide door, more than 42″, that is 1-3/4″ thick, and 8′ tall, than you need a door closer with an adjustable spring up to a size 5 or 6, or a fixed spring in that range. If it has to be ADA compliant than you would definitely want a size on spring, or a fixed size 1 spring.

If you door has a narrow stile (the frame around the glass), then you will need a Slimline closer. But if you do need a more heavy duty closer, you can still use them, but you will need a Drop Plate to mount the door closer body on. How far do you want the door to swing open? We can usually get closers to swing 180 degrees, it will only work on certain types of mounting (push, pull, top jamb), and varies manufacture to manufacture.

Getting the correct Door Closer can be difficult, but the more you know, the easier it will be. If you have any questions, just send us a comment and we will try and answer it as quickly as possible. We have been selling and stocking door closers for the past 45 years.

I have a door closer that started leaking oil, and now doesn’t provide any control over opening and closing speed of door. On the closer is:

Liberty R7483, LISTED 615R Door Closer Body. Any help would be appreciated!

Tom,

The number R7483 is found on many door closers. All of the closers made at a factory in Taiwan use that number, International and Global are the two that we sell. I would use this chart and line up the hole spacing to your current closer: https://www.rbadoor.com/door-closer-information.html .