A commercial door closer is an installed hardware device that creates a vacuum. This vacuum pulls the connector arm back, which closes a door after it’s been opened. Door closers can be used for commercial doors and residential doors but are more typically used commercially. Door closers need to be checked regularly as they may need adjustment or repair frequently. There are a variety of reasons why your commercial door closer may not be working properly and finding out why will help you determine what steps you need to take to repair your door closer. However, it’s important to not waste your time on incorrectly installed door closers, as they will not work properly and will have to be reinstalled.

How to Repair a Door Closer

Before you begin adjusting or fixing your door closer, you may need some materials, depending on the type of repair you are doing. These materials include:

- Rust Remover

- Grease and grease gun

- O-ring

- Pliers

- Adjustable wrench

- Screwdriver

First, you’ll want to look over the door closer and see if there are any other problems besides the one you’ve already noticed. Check if there’s any protruding screws and remove them, and make sure the control arm is working properly. Control arms can rust, get bent, be obstructed, or need lubrication. Additionally, if your door closer has a catch, make sure it is in open position. This will allow the control arm to close.

Door Closes Too Fast, Too Slow, or Slams Shut

If you are having a problem with your door closer’s closing speed, you’ll need to turn the speed adjustment screw. To slow the door closers closing speed, turn the screw clockwise. To increase the speed, turn the screw counterclockwise. If you want to prevent the door from slamming shut, you’ll need to adjust the latch speed with the latch adjustment screw. Like the speed adjustment screw, if you want to slow the door closer, turn the latch adjustment screw clockwise, or counterclockwise to increase the speed.

Lubricating Door Closers

Old door closers and door closers that have been exposed to outdoor elements may need lubrication to begin functioning correctly again. If there is any rust, use the rust remover and begin lubricating the door closer with the grease gun.

Door Closer Does Not Close Completely

If your door does not close completely, you’ll need to adjust the bracket. The bracket attaches the door closer to the door. Open the door and loosen the screws holding the bracket on the door and move the bracket more toward the door handle. Refasten the screws and check if your door is closing completely. If it still doesn’t, try removing the pin that secures the control arm to the bracket and move it to a hole that is farther away.

Door Closer is Leaking Oil

Leaking oil can cause the door closer to seize in place. To fix this, remove the adjusting screw. Then, use the rust remover to clean the screw and replace the O-ring. Make sure to lubricate before replacing the adjusting screw. Fasten the adjusting screw to the desired closing or latching speed level. Afterward, make sure no fluid is leaking and that the door closer is working properly.

Adjusting your door closer may need to be done occasionally. Luckily, it can be done quickly and easily by beginners. However, if none of these repairs work for your door closer, you may need to have it reinstalled or buy a replacement door closer.

]]>Is your Door Closer slamming? If it is we can help. They usually slam for a couple of reasons. The first being they are out of adjustment, either by wear and tear, or environmental issues. The second reason is due to failure of a seal or other component. By teaching you how to adjust it, and looking for telltale signs of the cause, we are here to help.

The first thing to understand is how a door closer works. Inside the cast aluminum or cast iron cylinder we have a spring pushing a piston. The piston is connected to a rack and pinion type device. When the closer opens, the arm which is connected to the spindle, moves the rack, which loads the spring. On the backside of the piston we have a fluid, which is usually something along the line of automatic transmission fluid. When the door is open, the spring pushes the fluid through channels in the casting. In each of the channels we have a control valve. This control valve regulates how fast the fluid is allowed to flow through the channel, which controls the closing speed. Think of it as a nozzle on your garden hose.

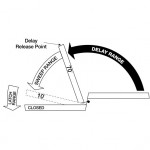

We usually have two valves that control the closing speed on commercial door closers. One valve is the Sweep Speed and the other is the Latching Speed. The Sweep Speed controls the amount of time it takes the door to sweep from 70 degrees open to about 15 degrees. The Latching Speed controls the amount of time it takes the door to move from 15 degrees open to the fully closed position. To slow either of these speeds, just tighten (clockwise) the adjustment screws, this will slow the speed of the hydraulic fluid through the channels, and slow the closer down.

The Sweep and Latching Speed valves are usually marked with a letter or number. The Sweep Speed valves are usually marked “C”, “S” or “1”, depending on the brand. The US made closers usually use the “C” or “S”, the imported closers usually use the number “1”. The Latching Speed valves are usually marked “L” or the number “2”.

The other adjustments we see on door closers are Back Check, Power, and Delayed Action. Back Check is the amount of resistance the door closer offers if it is thrown open by wind or vandals. Back Check usually starts at about 70 degrees and up. Power is usually on the end of the cylinder, and it is essentially a jack screw that increases or decreases the spring tension. The Power screw is also usually a larger screw or set screw. Delayed action is a valve to will hold the door open for up to 30 seconds to allow handicapped or the elderly through a door. For the Delayed Action to work the door must be opened to about 90 degrees.

If your Door Closer is slamming we need to look at a few things. The first thing I would do is inspect the door closer and look for any signs of fluid. Another thing to look for broken components on the arms, make sure everything is nice and tight. One of the last things would be the environment, has the weather changed, is the air conditioning now on?

Why do we inspect for fluid? One of the main reasons a door closer slams is the hydraulic fluid has leaked out, either threw the adjustment valves or the spindle seal. The spindle is what the arms attaches to, and they do fail, especially when the closer is mounted on the header, or top jamb. In these types of applications, the header tends to flex, which causes the closer to rock, which in turn wears out the seal. When the fluid has leaked out their is nothing to retard the motion, and the closer slams. What I would do is tighten the Closing and Latching Valves all the way, and then back them off a 1/2 turn. If it still slams then, the closer is shot.

The environment plays a roll sometimes. If your door closer is sitting in the sun, the casting will heat up, and the oil will become very thin, and fly through the valves. I would try the same thing as we did above, tighten the Closing and Latching Valves all the way, and then back them off a 1/2 turn.

Now we have either solved your door closer issue, or created a new one. If we have solved the issue, congratulations! If not, we need to get your door closer repaired, or replaced. When it comes to repairing them, I have had awful luck. After spending a couple of hours, the closer works and within a week it is leaking again. Replacing them might be the most cost effective way to get this thing fixed before someone gets hurt.

If you have an American made and manufactured door closer, they usually have a 10 to 25 year warrantee. The problem usually arises that you can not remember who you purchased it from, which the factories require. The factories usually want to know the Purchase Order Number the closer was purchased on. If your door closer is an imported version, usually the easiest way is to purchase another one, they are usually in the $50.00 range. We have our door closer information page on our website that lays out all of the door closer hole spacings and the models that are available with that pattern.

]]>There are a lot of LCN Door Closer applications out there. But with a little background, and some knowledge it is easy.

The story of the LCN Door Closer starts in 1880, when Louis C. Norton started the Norton Door Check company. It was one of the first door closers made, and was very bulky. In the 1920’s Norton sold his company, which went on to be called Norton Door Controls. After the legal 7 year buyout agreement, he started LCN, which were his initials. Small story, but interesting none the less.

A LCN Door Closer is supposed to control a door through the opening and closing process. I like to think of it in terms of energy. When the door is closed the closer has no energy, when it is fully open, it has its maximum amount of energy. When opening the door the energy is transferred from you to the door closer spring. When the door is closing it has to dissipate that maximum energy so it does not slam shut, that energy is transferred to the hydraulic fluid by being forced through valve, turn the energy in to pressure and then heat.

A LCN Door Closer will control the process like not other door closer made. During the opening process the function of the door closer is to allow the door to open as easily as possible, except at the end were back check will kick in. Back Check cushions the opening swing to prevent the door from hitting the stop with excess speed or force, all LCN Door Closers have Back Check. During the closing process the closer will maintain a uniform speed until the last few degrees of closing, the latching speed.

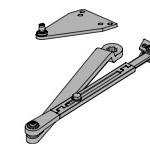

There are two types of the LCN Door Closer, one is called universal and the order is called application specific. A universal closer will work on a left or right hand door, along with the ability to be mounted on the push (parallel arm), pull (regular arm) or top jamb. For an application specific closer you have to specify the hand and type of mounting. There are benefits and draw backs on each of them.

The benefit of an application specific LCN Door Closer is they are usually more heavy duty, easier to adjust, and control the door better. With an application specific closer the engineers at LCN only have to account for forces in one direction. In a universal door closer you have to account for the forces in both directions. The forces on the application specific closer also apply to the door closer arm, again it is the same story with the forces in one direction. The draw back to application specific is you need to know the hand and the type of mounting you are using. Another issue is in larger buildings, were you have to stock extra closers, you will have to stock the different hands and mounting types for back ups. We this being said, application specific closers are recommended for institutional facilities.

The benefit of universal closers are for larger buildings. You only need to stock one closer, because one closer will work on all doors. Universal closers have been around for about 50 years, and the gap in durability to the application specific closers has been dropping quickly.

Another consideration for a LCN Door Closer is the amount of room on the door or door frame you have to mount it. We have narrow style and standard door closers. The narrow style is for aluminum framed glass storefront doors, but they can be used on any door. Narrow style door closers are usually designed to be installed on frames as narrow as 1-3/7″. Narrow style door closers are usually the least expensive, also. LCN offers the 1000 line closers for these applications. In the 1000 line we have the 1260, and 1460, which are the most heavy duty narrow line closers out there. The 1260 and 1460 are universal closers.

The LCN Door Closer 4000 line are the standard line closers. These closers are larger, but are much more heavy duty. We have the 4011, 4021, 4031, 4040XP and 4111 just to name a few. The 4011, 4021 and 4111 are application specific. The 4031 and 4040XP are universal closers.

The LCN Door Closer we have talked about all have the ability to use different arms. LCN makes arms for all different applications and that will be talked about at a later time.

If you have any questions on the LCN Door Closer, please drop us a comment or visit our website. We have access to all of the arms, covers and screws they offer, along with all of the template information at our finger tips.

]]>Getting the correct Door Closer can be difficult, but with a little back ground on there rating, materials, operation, type and new or replacement it is pretty easy.

A door closer has three rating levels in the industry, Grade 1, 2 and 3. Grade 1 is the heaviest duty rating and is usually means it has passed a 10,000,000 cycle test. Grade 2 is the next lowest rating, and they are tested for 2,000,000 cycles. Grade 3 is the lowest and the level is 1,000,000 cycles. The testing agency puts the closer on a test bed and lets them cycle through until they fail. They usually give up on Grade 1 closers after they get past 10,0000,000 cycles.

A door closer is usually made of cast aluminum or cast iron. Many of the inexpensive models are constructed of cast aluminum, and the more expensive door closers are made of cast iron. Cast aluminum is a softer material and over time will wear. The seals and adjustment valves on the aluminum closers will also wear and tend to leak over time. Cast iron is much more durable, and is very hard. We tend to see less issues with cast iron. If your door is going to have high traffic, or is in an abusive atmosphere I would recommend a cast iron door closer.

A good quality door closer will control the door when opening and closing. In the opening cycle it should create the least amount of resistance when opening and get more difficult toward the 70 degree point when the back check kicks in. Back check will control the door in case of a wind gust, or some one being abusive, kicking the door open. Back check will control the door so it does not slam into the door stop, or possibly a wall, and prevent the door from over rotating and damaging the hinges.

During the closing cycle the closer should close the door at a controllable speed. We have two controls and sometimes three. Just about every door closer made has a Closing and Latching Speed Valve. The Closing Speed valve controls the door from about 70 degrees down to the last 10 to 15 degrees. By tightening the valve you restrict the flow of hydraulic fluid flowing through the valve and it slows down. Latching Speed is amount of time it takes the door closer to swing the last 10 to 15 degrees.

A door closer can have a fixed spring or an adjustable spring. For almost 80 years door closers were shipped with a fixed spring. If you tried to install a size 5 spring on a smaller interior door it would of taken Hercules to open the door. In the 1970’s they started to manufacture adjustable spring tension door closers. With the adjustable spring you can adjust the tension the closer creates. If you have an interior bathroom door, you can turn the spring tension down so the door is easy to open, or if the door is exterior, you can increase to help close the door even if there is positive pressure in the building. Now schools and institutions could stock one door closer instead of many.

A door closer is going to be application specific or universal. Application specific means they are designed for one type of mounting and one hand. We have 3 types of mounting, push side (parallel arm), pull side (regular arm) or top jamb (top rail). For application specific a door closer would be designed for just one of the mountings. We do not see many of these anymore, but LCN Closers has the 4110 (parallel arm), 4010 (regular arm) and 4020 (top jamb). These application specific closers are usually more heavy duty, and last a long time. Universal door closer means they can be mounted on either of the three mountings, and are non handed, meaning they can go on a left or right hand door.

We also have size considerations for a new door closer. We have slimline and heavy duty closers. A Slimline door closer is one that has a 3/4″ center to center hole spacing on the vertical holes. This was done back in the late 1960’s with the advent of the narrow stile aluminum framed storefront door systems. The slimline closer was designed to mount on the top rail or top jamb, so it had to be narrow. The heavy duty closer is usually about 2-1/2″ on center for the vertical holes. The distance on the horizontal spacing does not matter, but the vertical height does.

Now that we have some back ground on the door closer, we need to figure out what your needs are. Is it for a replacement of an existing closer or is it a new door and closer.

If you are looking for a replacement closer, the first thing I would do is look for a manufacture name on the closer. If your closer has a cover, you might have to take the cover off and look on the inside of the cover for a model number, or it might be on a sticker. A little bit of information goes a long way. When we are helping customers find a replacement, we try to match the hole spacing, so there is very little work to do to install the new one. We have a Door Closer information page on our website, that lists the most common door closers and there hole spacing, this is a great place to start. With the knowledge you gained from the above information, you might even determine you need something more heavy duty.

Another thing we find on a door closer is a Listed Door Closer sticker. We usually find some thing like 320G Listed Door Closer. This is a UL sticker, or Underwriters Laboratory number. While it does not tell us which model you have, it does narrow it down to the manufacture you have. In this case 320G is a number we find on a LCN Door Closer.

If you are looking for a new door closer on a new door, I would ask yourself a few questions. How much traffic is the door getting, what is the weight of the door, what is the width of the door, does it have to be ADA compliant, how much room do you have to install the closer, how far does the door have to swing (90 or 180 degrees)

If you are installing it on a public building and every patron will be using this door, you might want something more heavy duty. But if you are installing it on your residential garage door, you might want something in the Grade 3 range. If you are installing a closer on a Public Library, than you definitely want to go Grade 1 Heavy Duty.

What is the weight, height and width of your door? If you have a wide door, more than 42″, that is 1-3/4″ thick, and 8′ tall, than you need a door closer with an adjustable spring up to a size 5 or 6, or a fixed spring in that range. If it has to be ADA compliant than you would definitely want a size on spring, or a fixed size 1 spring.

If you door has a narrow stile (the frame around the glass), then you will need a Slimline closer. But if you do need a more heavy duty closer, you can still use them, but you will need a Drop Plate to mount the door closer body on. How far do you want the door to swing open? We can usually get closers to swing 180 degrees, it will only work on certain types of mounting (push, pull, top jamb), and varies manufacture to manufacture.

Getting the correct Door Closer can be difficult, but the more you know, the easier it will be. If you have any questions, just send us a comment and we will try and answer it as quickly as possible. We have been selling and stocking door closers for the past 45 years.

]]>The Norton Door Closer 1601 has been around for the past 40 years. With the advent of aluminum framed glass doors, Norton was one of the first manufactures to come up with a narrow stile door closer. Since they did not have competition in this field for a few years, they built up a huge lead. It is still one of the most popular door closer models out there.

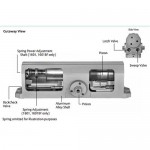

The Norton Door Closer 1601 is constructed of cast aluminum alloy. It features a 1-3/8″ diameter piston, and 5/8″ diameter pinion journals. The cylinder measures 9-3/4″ long by 1-3/4″ wide with a 2-3/4″ projection.

The Norton Door Closer 1601 is a Grade 1 closer (exceeds 10 million cycles) and has adjustable closing, latching, and back check speeds. The models we ship also have a multi sized spring. One for exterior doors and one for ADA and interior doors. The hole spacing is 3/4” x 9-1/16”. The reason you see the 3/4″ x 9-1/16″ hole spacing so often is because of the original Norton design. Everyone who manufactures door closers offer this hole spacing.

The Norton Door Closer 1601 has adjustments for closing speed, latching speed and back check, and optional delayed action. Closing speed is the amount of time it takes the door to go from 75 degrees of opening to the last 15 degrees. Latching speed covers the last 15 degrees of closing, so the door does not slam into the frame and create that crashing noise. Back Check controls the amount of resistant the closer offers if it is caught in a strong exterior wind, or the dreaded flying kung-fu kick. Delayed action the the ability of the door closer to delay the closing process when the door is opened past 80 degrees.

The Norton Door Closer 1601 also has an adjustable spring tension. This is accomplished through a jack screw on the end of the cylinder. We have two versions of the Norton Door Closer 1601, one is the 1601 and the other is the 1601BF. The 1601, which is the most popular, has an adjust for a size 3 to size 6 spring. The 1601BF is adjustable from size 1 to size 4.

In the old days before Multi Sized closers you had to have different closers for different sized doors and applications. The most popular was the size 4, which was for a 36″ exterior door. The Norton Door Closer 1601 will work on large interior doors, and most of your exterior doors. The 1601BF is for use on interior doors, and is adjustable all the way down to a size 1, which is what you would use for ADA applications. The size 1 can be turned down to 5 pounds of resistance.

The Norton Door Closer 1601 is non handed, and will work on the push, pull or top jamb mounting positions. Non Handed means it will work on the left or right swing door. It can be mounted on the push side of the door, also known as parallel arm mounting. Regular arm mounting is when the closer is mounted on the door, on the pull side of the door. The arm sticks straight out when it is mounted this way. The third way is called parallel arm mounting. In this configuration, the closer is mounted on the door, on the push side. When the door is closed the arm is parallel to the door.

If you have an existing door closer with a sticker that says 149A Listed Door Closer, you could have a Norton Door Closer 1601. But you could also have any of the other models of Norton or Yale Door Closers. Another interesting piece of information. Yale and Norton Door Closers are the same, but have different model numbers. So the Norton Door Closer 1601 is the same as the Yale Door Closer 51. The Norton Door Closer 9300 was the same as the Yale Door Closer 2300, ect… In the Norton factory they have two production lines. One line produces Norton Door Closers, the other produces the Yale Door Closers. This is good to know when you need a Yale replacement quickly. More companies stock the Norton product line, so chances are you can always find a replacement quickly.

Some of the older Norton Door Closer 1601 may be stamped with Scoville or Eaton, which are the companies that used to own Norton. Norton is currently owned by Assa Abloy. The newer 1601’s have 0251-4020 or 1621-04020 on the back of the cylinder. We also sometimes find 20-1624-4001, or 20-1604-4001 stamped on the back of the closer. If your door closer is stamped 20-1603-4001 or 20-1623-4001, you might want to double check the hole spacing. The 20-1603-4001 usually has a hole spacing of 3/4″ x 8-3/16″, you could use the International Door Closer 853 as a replacement.

The Norton Door Closer 1601 is one the most popular door closers manufactured today. It is a durable, heavy duty door closer that will be around for another 40 years.

]]>The Falcon SC71 Door Closer, uncompromising performance at a compromised price. Falcon SC71 door closer are heavy duty, and are built for applications that demand a reliable door control, easy maintenance and deliver tough performance. The Falcon SC71 is for use on interior or exterior doors in retail shops, restaurants, small offices and many other high traffic applications.

The Falcon SC71 Door Closer is Grade 1, ADA compliant, UL Listed. A Grade 1 door closer is a closer that is tested to 2,000,000 cycles, Grade 1 is the highest rated door closer available. An ADA compliant door closer is a door closer that meets the Americans with Disabilities Act requirements. These requirement usually mean the closer can be adjusted to offer less than 5 to 8 pounds of force to open the door. Less resistances is ideal for the elderly, handicapped and pre school aged children. Underwriters Laboratories (UL) is a government-approved company that carries out testing and certification to ensure products meet safety specifications. These standards are based on probable hazards associated with the product.

The Falcon SC71 door closer features an aluminum one piece casting with an 1-1/2″ diameter piston that is forged and heat treated. The benefit of a one piece casting is there are less opportunities for fluid to leak out, which would cause the closer to slam shut. The larger the piston, the lower the stress per square inch on the piston surface. The piston is also a forged part that is heat treated for greater strength and longevity. The pinion gear is double heat treated and the adjusting valves are staked. Double heat treating increases the surface strength of the gear. The pinion gear is what the arm attaches to, and connects the power of the spring to close the door. The adjusting valves are staked, which means when they are installed they are pressed into place, creating a tight valve seat. The tighter the valve seat, the lower the likelihood of oil leaking from the door closer.

The Falcon SC71 Door Closer has 4 and some times 5 adjustments. The first valve is the Latching Speed, with is the control over the last 7 to 10 degrees of closing. The second valve is the Main Speed, which controls the closer from about 70 degrees to the last 10 degrees of closing. The third valve is the Back Check valve, which controls the from 70 degrees and beyond, and is designed to slow the door if a gust of wind catches it. The fourth valve is the power adjustment. The power adjustment is so you can adjust the spring tension, for this door closer you can make the closer ADA Compliant, or increase the tension the full 9 turns for a 48″ exterior door. You can order this door closer with a fifth valve, and that would be the Delayed Action Valve. Delayed Action will hold the door in the 100 to 70 degree range for a specified amount of time so the handicap or elderly can make it through the door. In the below diagram the adjustment valves are on the back top of the closer.

The Falcon SC71 is also an non-handed door closer and can mount three ways. A non-handed door closer will work on a left or right hand door. This door closer can also be mounted Regular Arm (pull side), Top Jamb (cylinder on the top rail) or Parallel Arm (push side). This is ideal for institutions that need to keep a door closer or two in stock. One door closer will cover a wider range of installations.

We stock the Falcon SC71 Door Closer with the regular arm and parallel arm brackets, also known as SC71Rw/PA in the Aluminum (689) or Dark Bronze finishes (695). But this door closer is also available with the 9 other arm options. These include Hold Open, Extra Duty Arms, and Dead Stop Arms. And two other optional finishes, Matte Black (622) and Brass (696), all of the finishes are painted finishes.

The Falcon SC71 Door Closer uses a standard template, meaning the hole spacing on this door closer is used quite a few other door closers. The SC71 uses the same templating as the Norton Apollo Door Closer 7500, Yale Door Closer 4400, and the new LCN 4050 Rw/PA Door Closer. In all these cases the SC71 is almost $100.00 less expensive.

Before 2008 the Falcon SC71 Door Closer was known as the Dor-o-Matic SC71 Door Closer. They are not different door closer, they are the same. 2008 Ingersoll-Rand moved the Dor-o-Matic and Monarch name plates, and put them under the Falcon name plate. In 2014, they changed again, but they just rename the holding or parent company to Allegion from Ingersoll-Rand. The Falcon SC71 is sometimes called the Falcon SC70. The SC70 is the series name, of which the SC71 falls under that title. The SC71 just means the door closer has a fully adjustable spring tension and is ADA Compliant.

Installation of the Falcon SC71 Door Closer is simple. All of the screws and hardware are included the box. You simply tape the installation card on the door, and drill where and “X” is. The instructions are easy to read and on sturdy paper, not the inexpensive instructions we see on some of the imported door closers. And to make it easier, they even have an installation video shown below:

As you can see the Falcon SC71 Door Closer is a great valve, Grade 1, Non-Handed, Adjustable, and ADA Compliant. And has many options that you would only expect in the more expensive door closers.

]]>UL Listed Door Closer, we have written about these before, but we get so many inquires about so and so number Listed Door Closer I thought it might be a good time to revisit it. The following is an explanation on what Underwriters Laboratories does and what the UL Listed Door Closer means.

Underwriters Laboratories (UL) is a government-approved company that carries out testing and certification to ensure products meet safety specifications. These standards are based on probable hazards associated with the product. UL vigorously tests a sample of the product to determine how it reacts in each hazardous situation. If the manufacturer has proven it can create products that meet UL’s stringent safety requirements, it gets approved to carry the UL Listed mark.

Consumers, contractors and builders subsequently look to Underwriters Laboratories fire ratings when purchasing and using building materials. UL fire ratings for exterior walls and interior surfaces indicate which materials in a variety of categories are fire-resistant to a degree that agrees with National Fire Protection Association codes and standards as well as local building and fire codes.

Central to the matter of UL fire ratings, building codes and fire codes is the safety of a building’s inhabitants and inhabitants of nearby edifices.

UL fire ratings for walls also help to indicate what architectural features and materials to use in conjunction with fire-rated walls, such as doors. Ratings enable builders to install doors and windows with compatible UL fire ratings. Manufacturers disclose such ratings in product descriptions, and products bear a UL-rated or UL-certified sticker that indicates all relevant information to the builder, contractor or consumer.

The NFPA devises many of the codes and standards that local building code divisions uphold. UL is a global independent safety science company that tests building materials for both commercial and residential purposes. Since UL fire ratings adhere to NFPA standards and local building codes, the UL fire rating potentially indicates to building inspectors that materials within the building and exterior walls comply with local building and fire codes.

With this being said we usually find a number like 320G Listed Door Closer on all door closers. In this case the 320G Listed Door Closer is most likely a LCN Door Closer with a mechanical arm, meaning it does not hold the door open when pushed all the way open. We would find a different number on a LCN Door Closer with a hold open arm.

The Label 236N Listed Door Closer is usually found on Corbin Russwin Door Closers. Your closer might be a Corbin or a Russwin, but in 1994 Corbin and Russwin merged there product lines into Corbin Russwin.

Here is a list of numbers we know about, which is just a small sample but you will get the idea.

149A Listed Door Closer – Norton and Yale Door Closers

236N Listed Door Closer – Corbin Russwin Door Closers

320G Listed Door Closer – LCN Door Closers

615R Listed Door Closer – International Door Closers

669G Listed Door Closer – Dorma Door Closers

803H Listed Door Closer – Sargent Door Closers

805H Listed Door Closer – Sargent Door Closers

1038G Listed Door Closer – LCN Door Closers

R6684 Listed Door Closer – International Door Closer

R7483 Listed Door Closer – Global Door Controls

The above information should help you to an extent, but sometimes the easiest thing to do is measure the center to center hole spacing on your current door closer, and then visit our Robert Brooke and Associates Commercial Door Hardware Door Closer Information page to find a door closer that matches your hole spacing.

]]>The reasons to use the LCN 4040XP Rw/PA. Five years ago, LCN did a major redesign on the tried and true LCN 4040 Rw/PA Super Smoothee door closer. What they came up with was the Made in the USA, LCN 4040XP Rw/PA, eXtra Protection Door Closer. They came up with the 4040XP because of the influx of imported copies of the LCN 4040. These other companies were marketing there door closers as the same hole spacing as the LCN 4040 and stating they were just as good, they were not, but that is just an opinion. LCN had to make a statement, and boy did they ever. The new LCN 4040XP still has the same footprint, template, of the older LCN 4040, and the arms have not changed.

The 4040XP Rw/PA is LCN’s most durable and flexible heavy duty surface mounted closer, designed for institutional and other demanding high traffic applications. The LCN 4040XP Rw/PA sets a new standard for reliability, longevity and value with a better design and extraordinary performance testing that goes far beyond industry requirements. They built the 4040XP from the inside out, combining tougher, bolder construction with proven LCN technology. The result is a closer that’s stronger, smarter and delivers remarkable value in a variety of applications.

The patented green dial on the LCN 4040XP Rw/PA makes spring adjustments fast, easy and foolproof. The all-weather fluid reduces maintenance and ensures consistent performance through every season. High-traffic doors call for heavy-duty closers – closers that won’t let you down no matter how many people go through the door or how hard they kick, push or slam against it, or in the case of public schools the dreaded flying kung-fu kick. And when it comes to heavy-duty closers, no other closer performs like the LCN 4040XP Rw/PA.

The LCN 4040XP Rw/PA features cast iron construction, forged steel arm, double heat treated steel pinion, non-handed, LCN® “Green Dial” spring force indicator, Peel-n-Stick templates, UL and cUL Listed, 3⁄4″ journal diameter pinion, full compliment bearing, and tested and certified under ANSI standard A156.4, Grade 1.

Cast iron construction is a benefit most door closers do not have, most door closers are made of cast aluminum. Cast iron will not wear out like cast aluminum will. The forged steel arm, just means the chances of it bending or breaking are diminished. Forging the arm increases the surface strength of the metal. Double heat treating the steel pinion means the pinion is less likely to drop a tooth. Heat treating increases the surface strength of the gears on the pinion. The pinion on the LCN 4040XP Rw/PAis also 3/4” diameter, which is one of the largest diameters in the industry. The larger the diameter the lower the stress on the pinion teeth. All of this relates to a 44% increase in the Bearing Load capacity. The cylinder also incorporates the New V-shield seal, which should lead to a 20% longer seal life on he Spindle and Adjustment valve seals.

The LCN 4040XP Rw/PA cylinder is non handed, which means it will work on a right or left hand door, you only have to stock one closer, instead of two if you want to have a back up. The LCN 4040XP Rw/PA can be mounted on the push (parallel arm), pull (regular arm) or on the top jamb. The LCN Green Dial is how you adjust the power of the spring. In the old days, 20-30 years ago, you would need a door closer for a 36” interior door and a 36” exterior door. By turning the Green Dial you have the flexibility to use this closer on an ADA door, low resistance, or a 48” exterior door. The LCN 4040XP Rw/PA is designed for use on interior doors to 60” wide, and exterior doors up to 48” wide. This door closer also ships with Peel-n-Stick templates. This is very helpful in new applications, all you do is Peel and Stick the template to the door or door frame and you know exactly were to drill the mounting holes.

The LCN 4040XP Rw/PA also has adjustments for closing speed, latching speed and back check. Closing speed is the amount of time it takes the door to go from 75 degrees of opening to the last 15 degrees. Latching speed covers the last 15 degrees of closing, so the door does not slam into the frame and create that crashing noise. Back Check controls the amount of resistant the closer offers if it is caught in a strong exterior wind, or the dreaded flying kung-fu kick.

The UL and cUL certification labels tell us they are tested to the highest standards and meet the Underwriter Laboratories specifications, for non hold open door closers. Grade 1 means it has been vigorously tested for 10 million cycles, opening and closing.

Another great thing about the LCN 4040XP Rw/PA is the availability of replacement parts. All of the LCN Door Closers have parts break downs available. If for some reason the painters lose a cover, we would have them in stock! If your arm rod and shoe break we also have those on the shelf.

We stock and ship the LCN 4040XP Rw/PA, which is the non sized adjustable version of the 4040XP, and the Rw/PA means Regular Arm with Parallel Arm Bracket. The closer comes complete with cylinder plastic cover, regular arm, parallel arm bracket, and self reaming and tapping screws.

]]>We have been able to find a large stock of the Von Duprin 050709 Dogging Assembly, the older version of the Von Duprin Dogging Assembly used on devices shipped before 1997. The dogging assembly is the piece you put your 5/32″ hex key into and lock the exit device in the open position. This device was used on the 22, 33, 35, 98 and 99 Series devices. It some times went by the number Von Duprin part # 050153, but was updated to 050709 in the early 2000’s.

They are still manufacturing the Von Duprin 050709, but it is now done by another company and not Von Duprin. For many years we were not able to get this part, and many schools and institutions had to switch there dogging over to cylinder dogging to solve this issue. All that is involved to switch out the old style dogging assembly is remove the end cap, and slide the cover plate over to access the old dogging assembly. From there it is as simple as removing 2 to 4 screws and putting the new one in place.

The mounting plate measures 2-1/2″ x 1-11/16″,and the mounting screws are 1″ on center, the shaft uses a 5/32″ dog key. The Old Style Dogging Assembly can be ordered on our website von duprin 050709 old style dogging assembly . Our part # on this part is G050709 .

We stock replacement parts for all of the Von Duprin Exit Devices in our Troy Michigan Warehouse. We stock the old and new style dogging assemblies, latches, cover plates, strikes and screws. Visit our website for a detailed parts break down, which are readily available under the Panic Bars < Von Duprin < then the series that you have, at the top of the page. Most items ship out within 24 hours, and we offer FedEx shipping if you want your items sooner than later.

]]>We now have detailed LCN Door Closers Part Lists available online! Each parts break down has the complete arm break downs with the part number you need to order. We have them online for the 1460/1461, 4040/4041XP, 4010/4011, and 4110/4111 door closers. If you have a different model, just email us and we will get one off to you. These part break downs a big help in narrowing down what you really need, so you can get the correct part the first time. These are factory break downs, and most of these parts we have in stock for immediate delivery. If we do not have, we can order them , and they usually ship in 5 days or less. These part breakdowns can be found on our commercial door website.

]]>