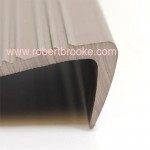

One of the biggest decisions is whether to use rubber or vinyl stair treads. Rubber has a lot of positives attributes, like appearance, long life and higher friction coefficient. Some of the negatives are price and cost of shipping. The cost is due the fact that each rubber stair tread is individually molded, which means they are made one at a time, which very labor intensive. Because the rubber treads are molded, they can have patterns on them like raised disc’s, squares or rectangles. Vinyl Stair Treads on the other hand are extruded through a die, the result is a continuously fed piece, which is much more cost effective. Because they are fed through a die, the only pattern they can have are continuous ridges along the fall line. The R.C. Musson 400 Series Heavy Duty Vinyl Stair Tread is perfect compromise for the rubber stair treads. This stair tread features a 1/4″ thick tread at the nose, 12″ deep tread and a nose that drops 1-1/4″. This tread has 21 ridges that run the length of the tread to prevent slipping. They come in 24, 30, 36, 42, 48, 60, 72, 84, and 96″ widths, and are easily cut in the field with a straight edge and a utility knife.

]]>